In the mixing department the moulding compounds are prepared for different types of rubber bottoms.

The compounds are then cut and weighed by an extruder allowing the creation of pieces of raw rubber

for different kinds of articles and sizes.

Each compound is subjected to rigorous laboratory tests to ensure the production of a quality product

which meets the required technical requirements and is guaranteed for the customer.

Processing steps

Mixing

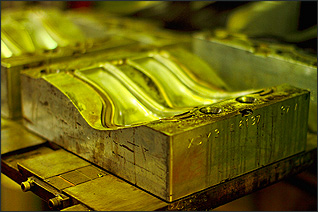

Moulding

The previously created rubber now goes through the moulding and vulcanization processes

through the compression moulding presses.

Trimming

The rubber soles obtained after moulding, are trimmed and controlled manually one by one,

prior to be sent to the packaging and shipping department.

Contact us for any informationsFill the form

SAG-ITALIA srl | Via Molino 1 - Castelbellino (AN) - Italia | T (+39) 0731.70.20.32 | F (+39) 0731.70.25.59 | C.F./P.Iva 02296200427